NX Stami™ Digital Performs First Remote Site Acceptance Test

NX Stami™ Digital has completed its first remote Site Acceptance Test (SAT), the final stage in the development of the customized Technology Training Simulator (TTS) that will be used to train the operators of the MOL Group’s new HPPO (Hydrogen Peroxide to Propylene Oxide) plant at MOL Petrochemicals site in Tiszaújváros, Hungary. The HPPO plant is the heart of the new Polyol Complex under construction by thyssenkrupp Industrial Solutions (tkIS) and the licensor of the HPPO process is tkIS and Evonik (TE). The EUR 1.2 billion Polyol Project is the largest single organic investment in the history of MOL Group.

The development of the TTS for the HPPO plant started with a kick-off meeting in February 2020. Following the model validation and factory acceptance tests, which were performed earlier, the SAT marked the successful completion of the TTS.

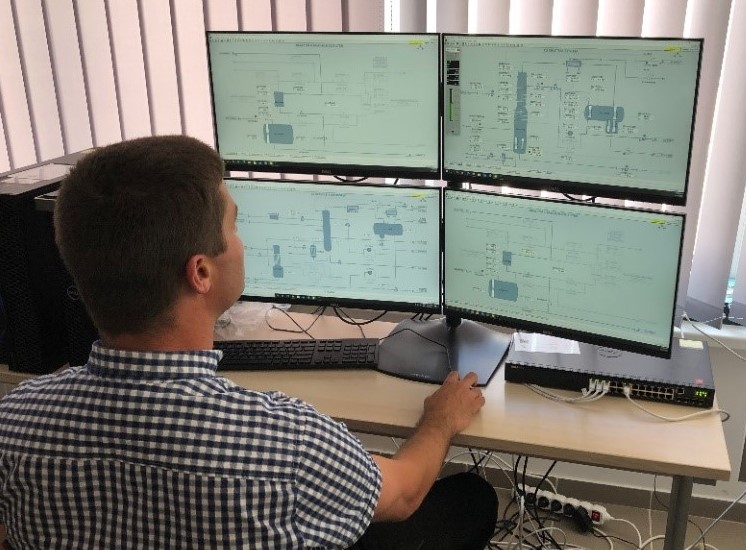

The test included checking the availability of pre-requisites, hardware and software checks, and functionality testing of the stations across different scenarios. Typically, during this stage of the development TTS stations are tested on site over a two-day period but this time the test was completed remotely.

“This project has played a significant role for us, as we had to overcome the limitations imposed by the pandemic, thus increasing our capability of performing remote testing,” said Jesús González Rebordinos, Digital Process Engineer at Stamicarbon and the lead engineer for the project.

NX Stami™ Digital developed the model and the TTS application and delivered a high-fidelity TTS comprised of one Instructor Station and two Trainee Stations, along with required licenses, hardware, software and training on how to use the software. The TTS application has the following features:

- Capability to run in real-time with the possibility of acceleration

- Capability to run pre-defined scenarios

- Behavior, look and feel of the actual distributed control system (DCS)

- Full emulation (process simulation, DCS logics emulation)

- 98% accuracy or higher

With the TTS, the end user can train operators more efficiently on start-up and shutdown procedures, day-to-day plant operations and other scenarios. Instructors can grade or score trainees based on their responses to certain scenarios and develop new scenarios for training. Moreover, operators can test different scenarios to determine their applicability in the actual plant environment.

“All of us highly appreciate Stamicarbon’s hard work, professional attitude and commitment,” said Dr. Richárd Sági, Lead Process Engineer at MOL Group. “Now having hands-on experience with the TTS, we are even more confident that it is going to largely contribute to the successful commissioning and operation of our HPPO plant.”

NX Stami™ Digital TTS

Stamicarbon develops high-fidelity TTS for a wide range of customers. “Developing a TTS for an HPPO plant is very different from developing a TTS for a fertilizer plant,” González Rebordinos said. “Stamicarbon has specialized knowledge of different processes, allowing us to develop custom training solutions tailored to meet the requirements of our clients across different industries.”

Learn more about NX Stami™ Digital TTS below