At Stamicarbon, we believe that equipment reliability and expert support can make all the difference. Our team of specialists is ready to take on any challenge, applying their deep expertise to solve complex issues in fertilizer production. That’s why we’re excited to introduce Dr. Stami, Prof. Next, and their rival, Oxide—the stars of our new comic series, inspired by real-life case studies from the nitrogen industry.

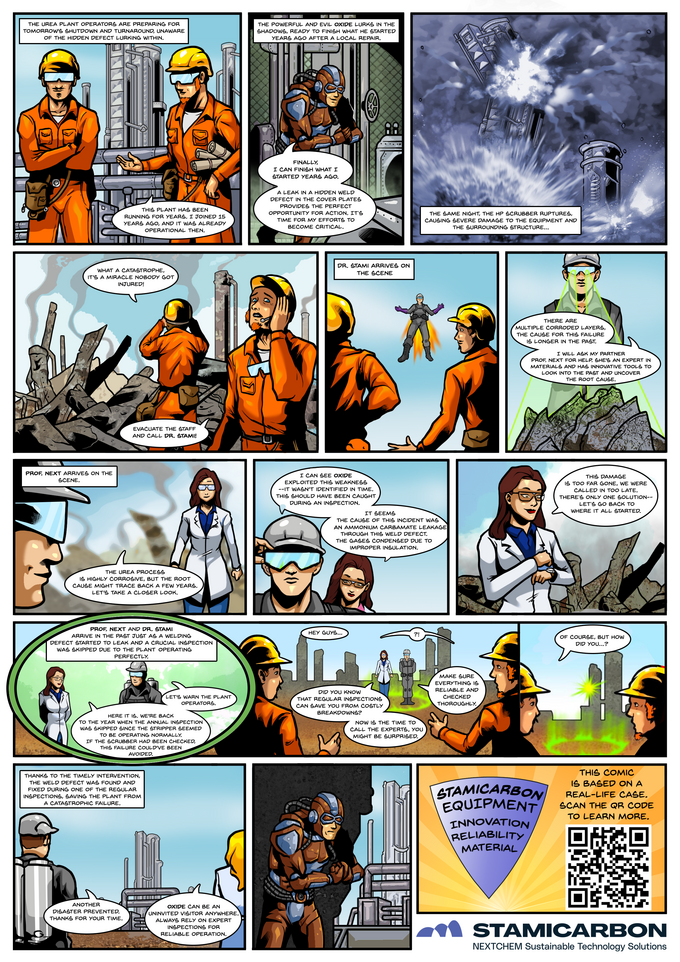

Prof. Next

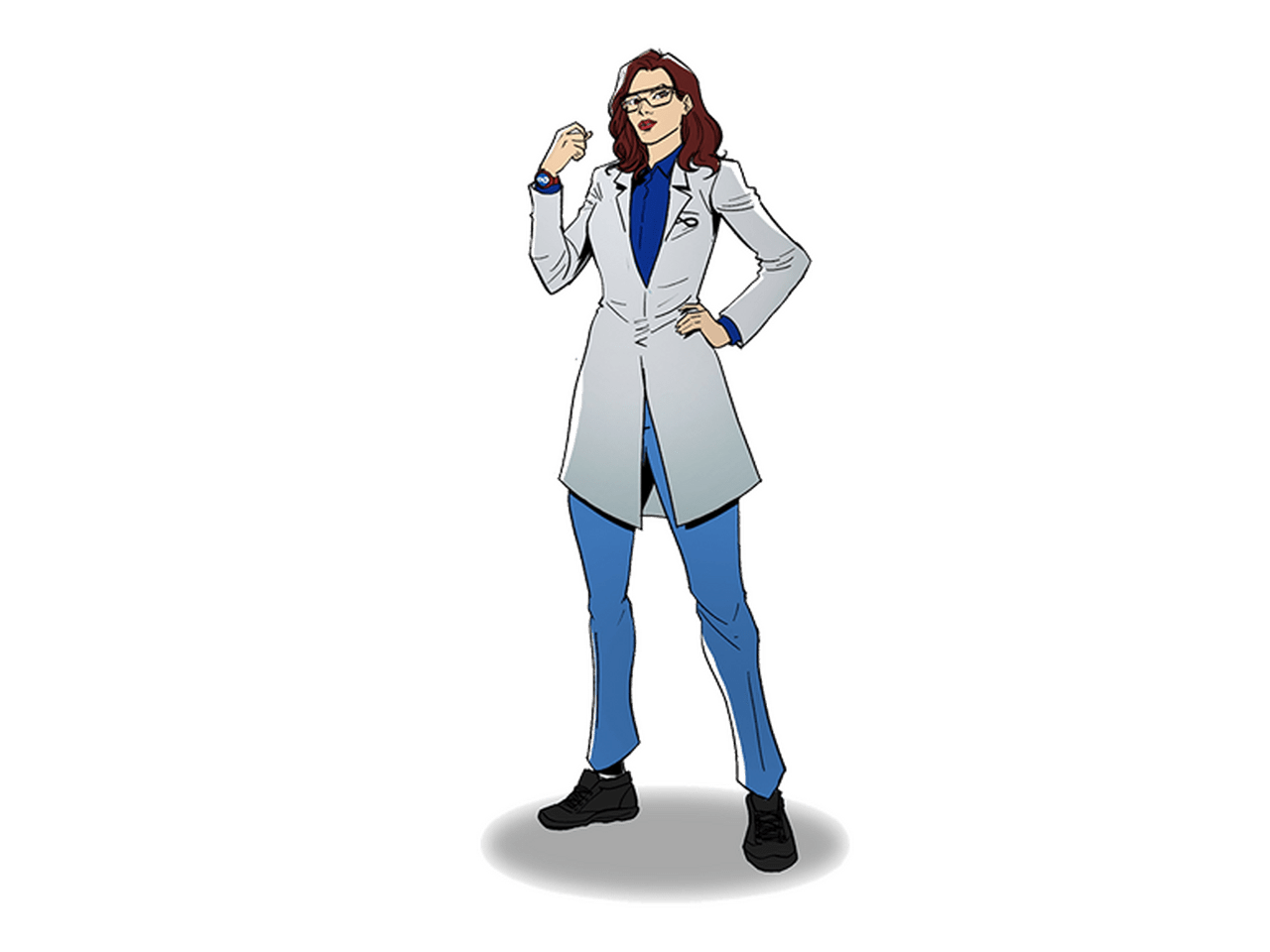

Dr. Stami

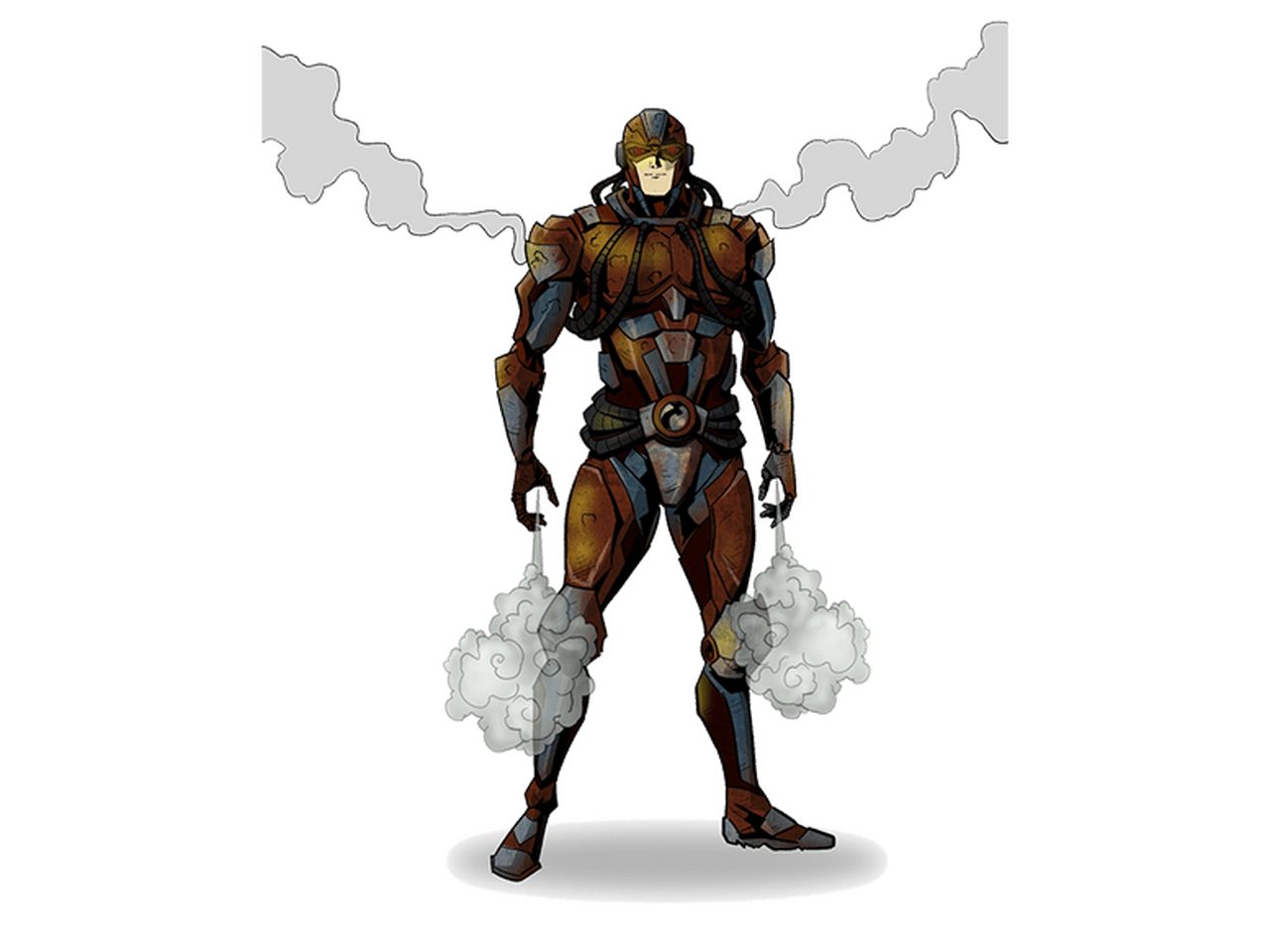

Oxide

Dr. Stami – The Guardian of Equipment Integrity

An experienced expert and engineer, Dr. Stami is the ultimate specialist in materials and process solutions. Armed with deep technical expertise and a toolbox of his incredible inventions, he diagnoses equipment vulnerabilities and provides tailor-made solutions to ensure reliability and longevity.

Prof. Next – The Visionary of Time-Proof Plants

A forward-thinker with innovative tools that allow her even to travel through time, Prof. Next can help predict potential failures before they happen. By leveraging advanced diagnostics tools and technology insights, she helps Dr. Stami prevent issues before they escalate, keeping operations efficient and safe.

Oxide – The Silent Threat

A relentless rival to our heroes, Oxide represents the forces of corrosion, wear, and degradation that threaten any nitrogen fertilizer plant performance. Left unchecked, his influence can lead to unexpected failures—but with the right expertise, he can always be defeated.

Battle against Corrosion

In this adventure, Dr. Stami arrives just in time to save a critical high-pressure urea reactor from total failure.

As Oxide is about to corrode the reactor wall, exploiting the hidden liner weld defect, our expert arrives to prevent a catastrophe.

Dr. Stami wins the battle with his unmatched expertise in materials and applying cutting-edge technology.

Case Study

This paper explores a catastrophic failure at a urea plant caused by process-side corrosion.

The incident occurred in the urea reactor of a CO₂ stripping plant that began operations in 1994.

Download the full case study to see how expert intervention helped restore production and safeguard plant integrity.

Crisis in Urea Plant

In this episode, Dr. Stami and Prof. Next investigate the catastrophic rupture of a high-pressure scrubber.

This time, the powerful and evil Oxide has succeeded, exploiting a hidden ammonium carbamate leakage.

Could this major failure have been prevented? Only our heroes have the expertise and tools to uncover the truth.

Case study

Just two days after a maintenance shutdown, the dome of a high-pressure scrubber in a CO₂ stripping urea plant was violently ejected, damaging nearby equipment.

An in-depth investigation revealed the cause — a defective fillet weld in a cover plate that allowed ammonium carbamate to leak behind the liner. Corrosion progressed undetected due to a plugged leak detection hole.

Download the full case study to learn how this failure unfolded and how you can prevent similar risks in your own plant.