Choosing the right technology for a urea plant involves a critical balance between capacity, capital expenditure (CAPEX), and operational expenditure (OPEX).

At Stamicarbon, we leverage our decades of innovation to offer tailored solutions that meet these specific demands. Building on the legacy of our groundbreaking CO2 stripping process, we have developed two distinct melt technology designs to ensure your plant is not only efficient and stable but also perfectly scaled to your production needs and investment strategy.

Our CO2 stripping process designs simplify your plant’s overall design. Capital investment is reduced due to the compact designs that require less equipment. This makes the process easier and more stable, and your plant is much less maintenance-intensive.

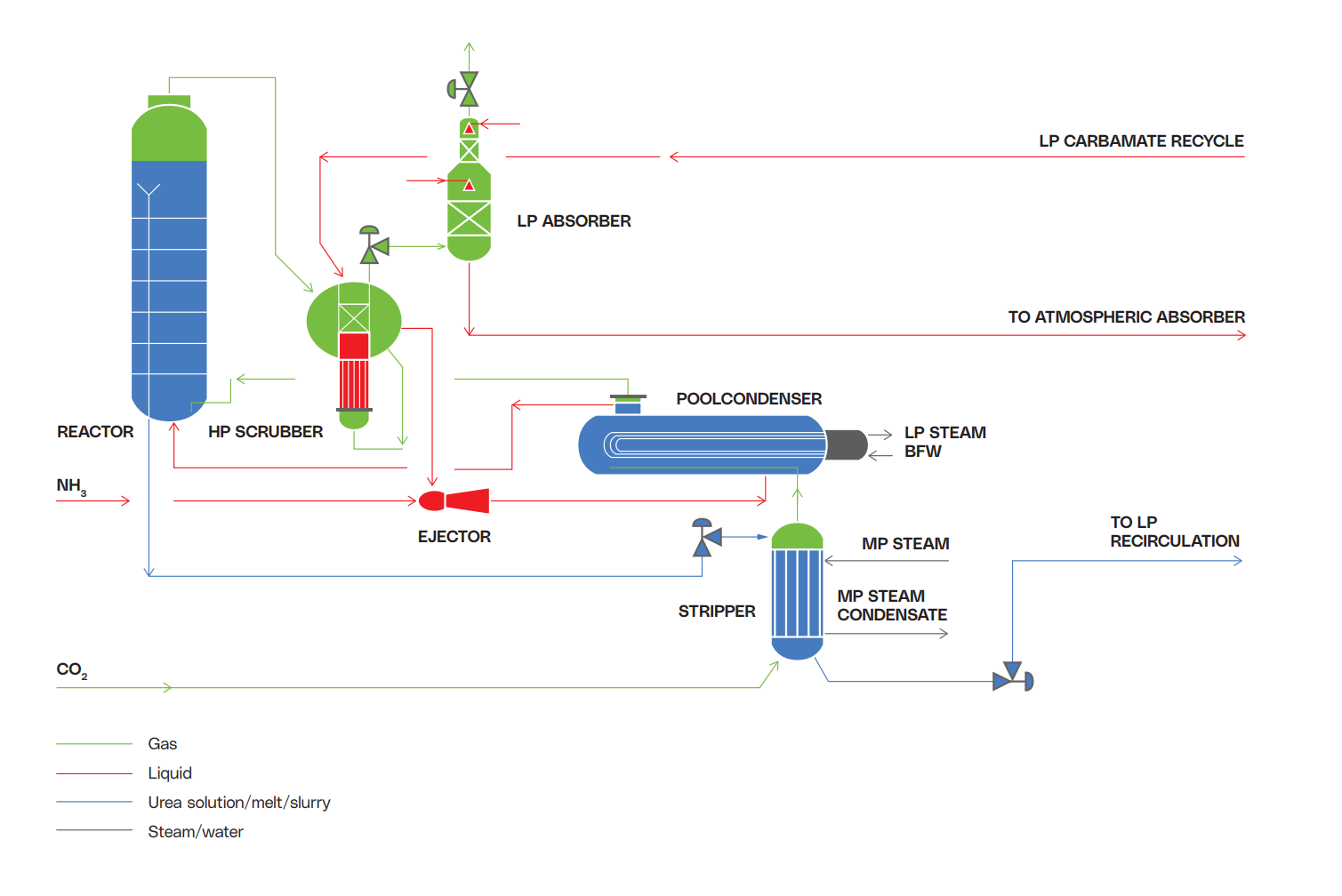

Pool Condenser Design

This widely used design guarantees optimal heat transfer, excellent process stability and high onstream time. It includes a high-pressure pool condenser combined with a relatively short vertical reactor.

If you want the most efficient technology for capacities from about 2500 up to 6000 metric tons per day (mtpd), this is it!

How a Pool Condenser Design Works

Ammonia and carbon dioxide are introduced to the high-pressure synthesis using a high-pressure ammonia pump and a carbon dioxide compressor.

The ammonia then drives an ejector, which conveys the carbamate solution from the high-pressure scrubber to the pool condenser. In the high-pressure stripper, the carbon dioxide, entering the synthesis as a feed, flows countercurrent to the urea solution leaving the reactor.

On the shell side, the high-pressure stripper is heated with steam.

The off-gas of the high-pressure stripper, containing the carbon dioxide, together with the dissociated carbamate, is then fed into the pool condenser, where ammonia and carbon dioxide are condensed to form carbamate.

The heat released by condensation and subsequent formation of carbamate is used to produce reusable low-pressure steam.

After the pool condenser, the remaining gases and a liquid containing urea and carbamate enter the vertical reactor. Here, the final part of the urea conversion takes place.

The urea solution then leaves the top of the reactor (via an overflow funnel) before flowing back into the high-pressure stripper.

Ammonia and carbon dioxide conversions in the synthesis section of a Stamicarbon carbon dioxide stripping plant, are particularly high.

As a result of that, our CO2 stripping process is the only commercially available process that does not require a medium-pressure recirculation stage downstream from the high-pressure stripper. Gases leaving the reactor are fed into the high-pressure scrubber.

Here, the gases are washed with the carbamate solution from the low-pressure recirculation stage.

The enriched carbamate solution is then fed to the high-pressure ejector and, subsequently, to the pool condenser.

Inert gases, containing some ammonia and carbon dioxide, are then released into the 4-bar absorber.

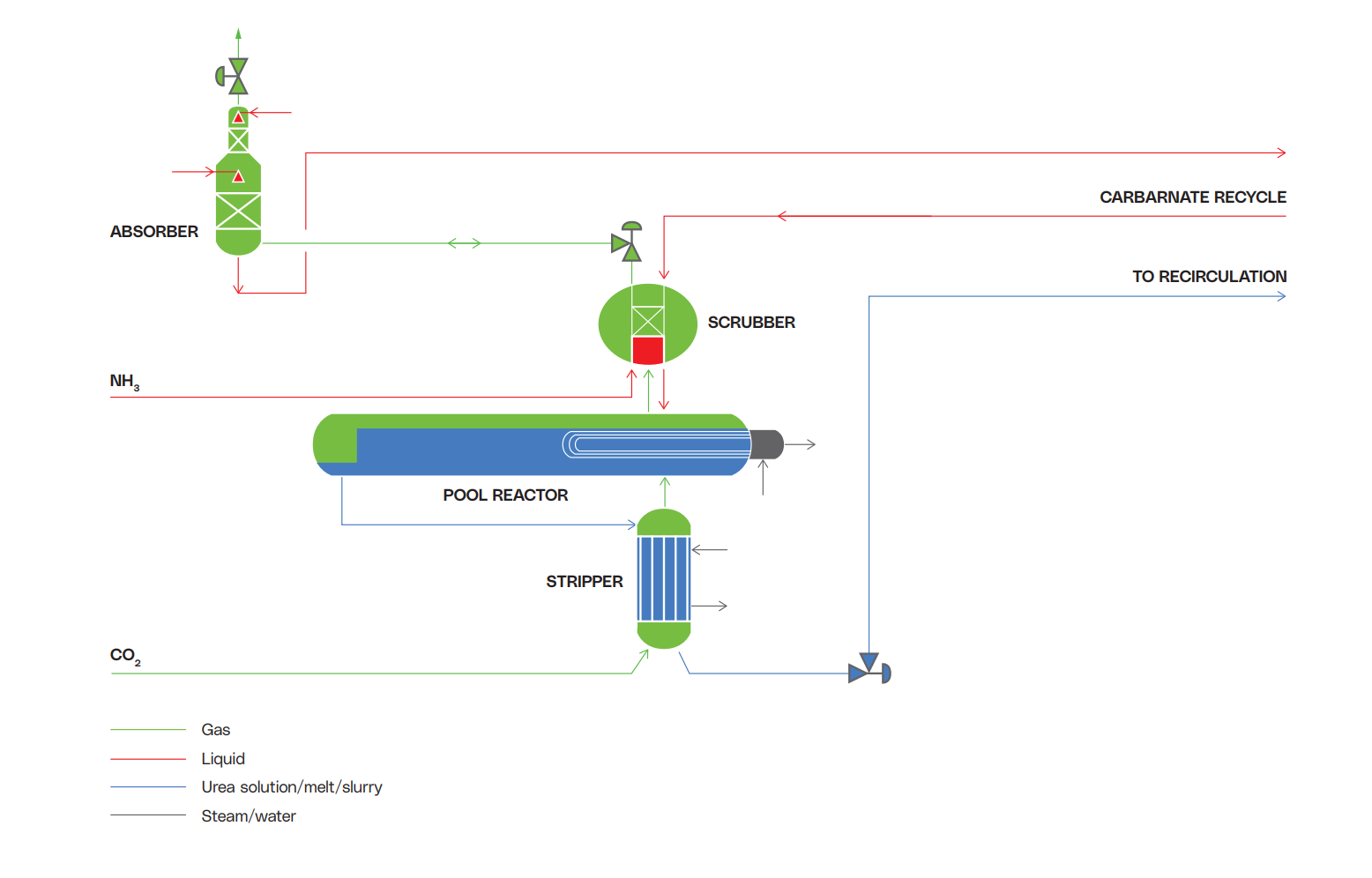

Pool Reactor Design

If you are looking for a low-height plant design with minimal piping and high-pressure equipment, Stamicarbon Pool Reactor Design can provide all you wish for.

Our specific design integrates the pool condenser and a vertical reactor into one piece of equipment: the pool reactor. It is perfectly suited for smaller capacities up to about 2500 metric tons per day (mtpd).

How a Pool Reactor Design Works

Unlike the Pool Condenser concept, the Pool Reactor concept combines the condenser and reactor in a single pool reactor.

This is achieved by enlarging the horizontal condenser so as to incorporate additional reactor volume.

As a result, it becomes possible to achieve sufficiently high residence times, eliminating the need for a separate vertical reactor, while creating the conditions that will allow the reaction to reach its optimum condition with the advantage of having a plant height of about 30 meters.

The high-pressure scrubbing operation can also be simplified in the Pool Reactor concept by placing the scrubber sphere above the pool reactor and adding the ammonia to the synthesis via this scrubber.

This ensures that no separate heat exchanging section in this scrubbing operation is required. In the Pool Reactor concept, carbamate from the low-pressure recirculation section flows together with the absorbed gases and the ammonia into the pool reactor.

As the static liquid height ensures gravity flow, no high-pressure ejector is needed.